取消

清空记录

历史记录

清空记录

历史记录

特点 Characteristics

更易润湿,降低润湿剂用量:

采用负压分散+高剪切均质复合工艺,通过真空环境破除粉体(如陶瓷颗粒、纳米氧化物)表面气膜,使液体润湿剂快速渗透至粉体间隙,润湿效率提升,润湿剂用量减少。

Easier to wet, can reduce the amount of wetting agent:

Negative pressure dispersion + high shear homogeneous composite process, through the vacuum environment to breaksurface alir film of the powder (such as ceramic particles, nano oxides), so that the liquid weting agent quickly penetrate into thepowder interstices, wetting efficiency is improved, the wetting agent dosage is reduced.

杜绝空气,能迅速脱气、降低消泡时间和消泡剂用量Eliminate air, can quickly degas, reduce defoaming time and defoamer dosage

。1.5H的制浆时间,提高生产效率1.5H pulping time for improved productivity!

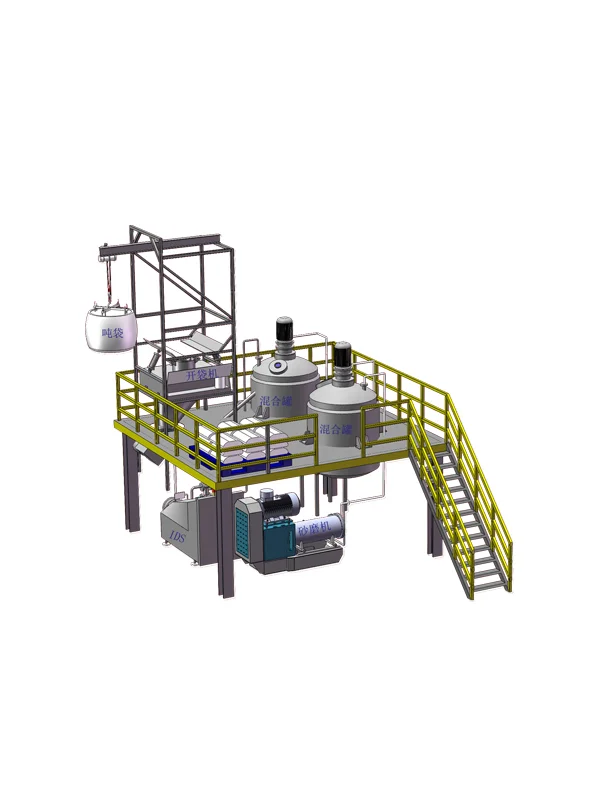

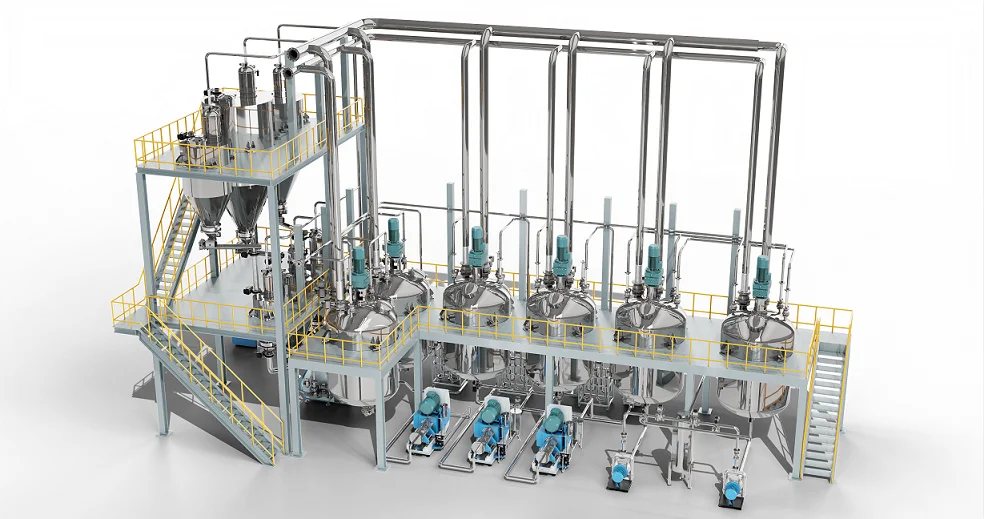

原料预处理:无尘输送系统与恒温储罐联动,实现粉液原料的**计量与瞬时混合;Raw material pre-lreatment: Dust-free conveying system is linked with constant temperalure storage tank to achieve accuratemeasurement and instant mixing of powder and liquid raw materials;

分散研磨:砂磨机与高压均质机并联运行,通过多级粒径反馈控制,将传统6小时的制浆周期压缩至1.5小时,产能提升。Dispersion grinding: The sand mill and high pressure homogeniser are operated in parallel, and through multi-stage particlesize feedback control, the traditional 6-hour pulping cycle is compressed to 1.5 hours, with increased production capacity.

应用领域:

MLCC及电子陶瓷介质材料、固态电池电极与隔膜涂覆材料、 **功能性涂覆材料等行业,具体来说包含:钛酸钡等介质材料的纳米级分散与研磨、氧化铝等固态电池用陶瓷隔膜涂覆材料。光学膜材: 如聚酰亚胺、铯钨青铜纳米浆料,用于制备高透明、隔热等功能薄膜等材料。

涂覆材料自动化产线

特点 Characteristics

更易润湿,降低润湿剂用量:

采用负压分散+高剪切均质复合工艺,通过真空环境破除粉体(如陶瓷颗粒、纳米氧化物)表面气膜,使液体润湿剂快速渗透至粉体间隙,润湿效率提升,润湿剂用量减少。

Easier to wet, can reduce the amount of wetting agent:

Negative pressure dispersion + high shear homogeneous composite process, through the vacuum environment to breaksurface alir film of the powder (such as ceramic particles, nano oxides), so that the liquid weting agent quickly penetrate into thepowder interstices, wetting efficiency is improved, the wetting agent dosage is reduced.

杜绝空气,能迅速脱气、降低消泡时间和消泡剂用量Eliminate air, can quickly degas, reduce defoaming time and defoamer dosage

。1.5H的制浆时间,提高生产效率1.5H pulping time for improved productivity!

原料预处理:无尘输送系统与恒温储罐联动,实现粉液原料的**计量与瞬时混合;Raw material pre-lreatment: Dust-free conveying system is linked with constant temperalure storage tank to achieve accuratemeasurement and instant mixing of powder and liquid raw materials;

分散研磨:砂磨机与高压均质机并联运行,通过多级粒径反馈控制,将传统6小时的制浆周期压缩至1.5小时,产能提升。Dispersion grinding: The sand mill and high pressure homogeniser are operated in parallel, and through multi-stage particlesize feedback control, the traditional 6-hour pulping cycle is compressed to 1.5 hours, with increased production capacity.

应用领域:

MLCC及电子陶瓷介质材料、固态电池电极与隔膜涂覆材料、 **功能性涂覆材料等行业,具体来说包含:钛酸钡等介质材料的纳米级分散与研磨、氧化铝等固态电池用陶瓷隔膜涂覆材料。光学膜材: 如聚酰亚胺、铯钨青铜纳米浆料,用于制备高透明、隔热等功能薄膜等材料。

浏览器自带分享功能也很好用哦~

浏览器自带分享功能也很好用哦~